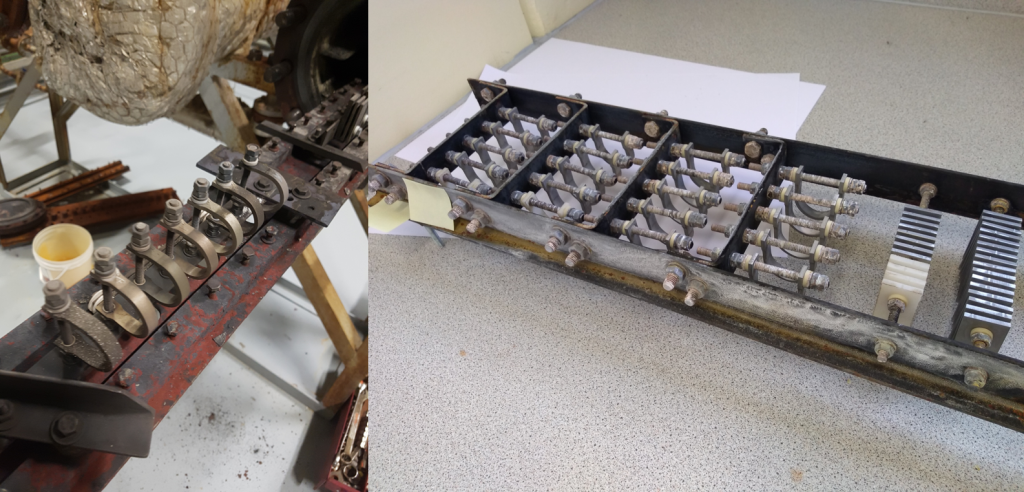

Picture: The test heat exchanger at Soultz-Sous-Forêts, France (Source: ES)

Corrosion is a form of damage that metals can experience when in contact with certain environments. Corrosion causes the metal to degrade which can lead to reduction in strength and leaking. There are numerous corrosion forms and the type of corrosion a component experiences is dependent on the environment, material and design of the system. In geothermal utilization, corrosion is a key component to consider for sustainable exploitation. Indeed, damage due to corrosion processes can induce loss of production in addition to operational and maintenance costs.

Scaling in geothermal systems is caused by a change in the equilibrium of the geothermal fluid, which induces certain elements to precipitate. In geothermal systems it is common to find silica and calcite scaling although other forms of scaling are possible depending on the chemical composition of the fluid reservoir. Scaling in heat exchangers can cause clogging in the system which can lead to substantial reduction of efficiency. If scaling builds up, it is necessary to clean it through routine maintenance to allow the system to operate properly. How easy it is to clean however is highly dependent on the design of the component and the composition of the scale.

In the MEET project the focus is on using ORC (Organic Rankine Cycle) systems to utilize low to medium temperature geothermal resources for electricity production. Instead of geothermal fluid, a second fluid (organic one) with a lower boiling point is used to drive a turbine and generate electricity. The thermal transfer between the fluids is obtained using a heat exchanger. In the case of these systems the only component that comes into direct contact with the geothermal fluid is the heat exchanger. The heat exchanger is therefore the main component within the ORC system that could encounter issues due to exposure to geothermal fluid. These problems can range from reduced efficiency of the system to detrimental failure and they can usually be linked to scaling and corrosion.

Within the MEET project, preliminary material tests in geothermal fluid have been performed in different geological settings (volcanic, sedimentary and granitic reservoirs). These tests have focused on finding appropriate materials for ORC heat exchangers utilizing low-medium temperature geothermal resources, by evaluating the effect scaling and corrosion has on the materials in these different environments. Scale and corrosion characterization is ongoing by MEET partners (ICI, CY University, ESG).

The material tests were performed both in France and in Iceland and showed both different corrosion resistance and scaling build-up. This allowed for down selection of the heat exchanger material which is now being used for actual testing of the ORC systems in these different environments. These initial tests are scheduled to finish in 2020 and will give both results on the efficiency of the system along with further results on the susceptibility of the heat exchanger materials to scaling and corrosion in geothermal operation.

Figure: Preliminary material testing for the heat exchangers in MEET (source: ICI)

Latest related articles:

– Heat Exchanger Test at Soultz-Sous-Forêts EGS Power Plant : https://www.meet-h2020.com/heat-exchanger-test-at-soultz-sous-foret-egs-power-plant/

– ORC installation in Vermilion Site (Chaunoy, France) : https://www.meet-h2020.com/organic-rankine-cycle-installation/