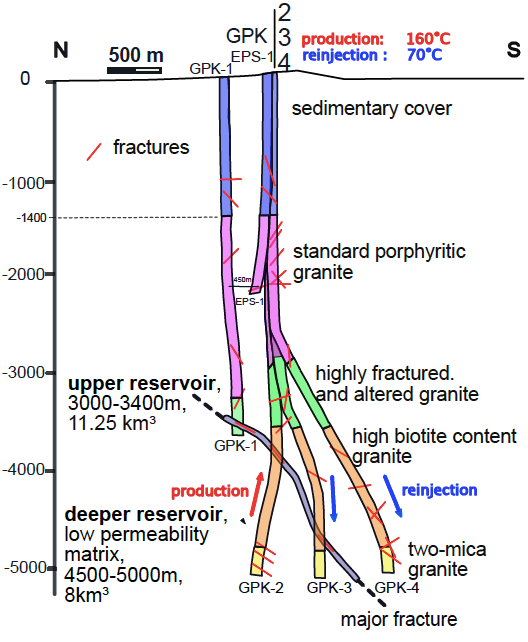

The aim of the Soultz-sous-Forêts Geothermal Power Plant (SGPP, Upper Rhine Graben, France) is to optimize the exploitation of a fractured granitic reservoir (Figure 1), while minimizing environmental issues. In MEET project, this demo-site is tested for enhancing energy production. To this aim, the temperature of the reinjected fluid is to be lowered from 70°C to 40°C in order to increase the extraction of heat of up to 20-35%. A test was run during 3 months in 2019 with a prototype Small-scale Heat EXchanger (SHEX) into which 10% of the total flow was diverted. One of the main risks is a potentially increased production of scales inside the SHEX with temperature lowering. Scales were investigated from thickness, mineralogy and chemical composition points of view, as described below.

Figure 1: The Soultz-sous-Forêts fractured granitic reservoir and the 3 exploited drill holes (GPK-2, GPK-3 and GPK-4).

ESG and CYU worked together to study the scaling phenomenon at Soultz in a small prototype exchanger. The temperature of the geothermal fluid produced from GPK-2 deep well is around 160°C. At present, the fluid is reinjected at a temperature close to 70°C in GPK-3 and GPK-4. The temperature of reinjection was tested at 40°C during the 3 month-trial (January to April 2019) in the SHEX. It was designed to cool down the brine to 40°C with 4 passes. The Soultz geothermal fluid is a highly saline brine. To ensure the best resistance to corrosion, the SHEX was constructed with six different metallurgies. The cooling of brine in the exchangers promotes the precipitation of scales. The aim of this study was to compare the mineralogy, chemistry and thickness of the scales, from the reference state (before lowering of reinjection temperature) to those obtained with various metallurgies after three months of continuous geothermal fluid circulation at three different lower temperatures (60°C, 50°C and 40°C).

Constant features among the scales obtained in contact with the 6 metallurgies in the SHEX are:

1) The scales are granular, mainly composed of Pb, As, Sb and S occurring as sulfides (galena). Other metals are present as traces. The composition of the scales shows only very slight variations with the different metallurgies. On the opposite, Pb, As and Sb concentrations vary with temperature.

2) Halite (NaCl) is also encountered as large square patches (millimetric size) or as small cubic crystals (micrometric size),

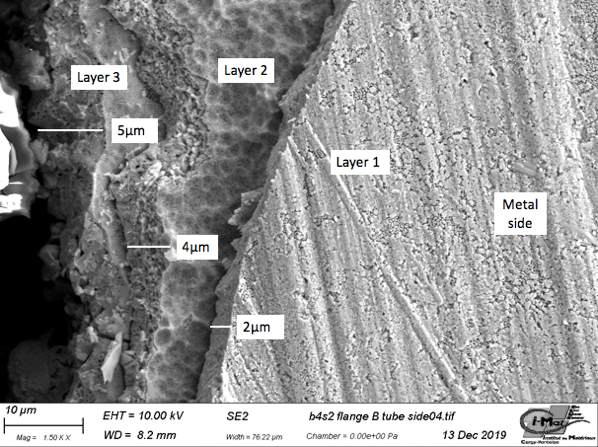

3) Scales are frequently compact and composed of several layers (Figure 2) or sometimes occur as a powder.

4) The thickness of scales tends to increase when the temperature lowers, which is important for the operation of the power plant.

5) This scale composition is identical to that currently encountered in SPP exploitation when reinjecting at around 70°C.

6) No new type of deposition was triggered by decreasing temperature down to 40°C.

This characterization of scales is a key feature for the optimization of the heat exchanger: the thinner the scales, the better the heat exchange. In addition, a good knowledge of scales allows a better formulation of scale inhibitors, and potentially a better identification of the cleaning process to implement. Additional analyses should be performed to better characterize the geochemical and mineralogical composition of the scales in order to point out the presence or not of Pb, As and Sb either in the form of metal-sulfides or of native metal. This will be an important information to differentiate the processes triggering the scale formation, i.e. thermodynamic effects or electrochemical corrosion.

Figure 2: Example of scales occurring as several layers (SEM micrograph)