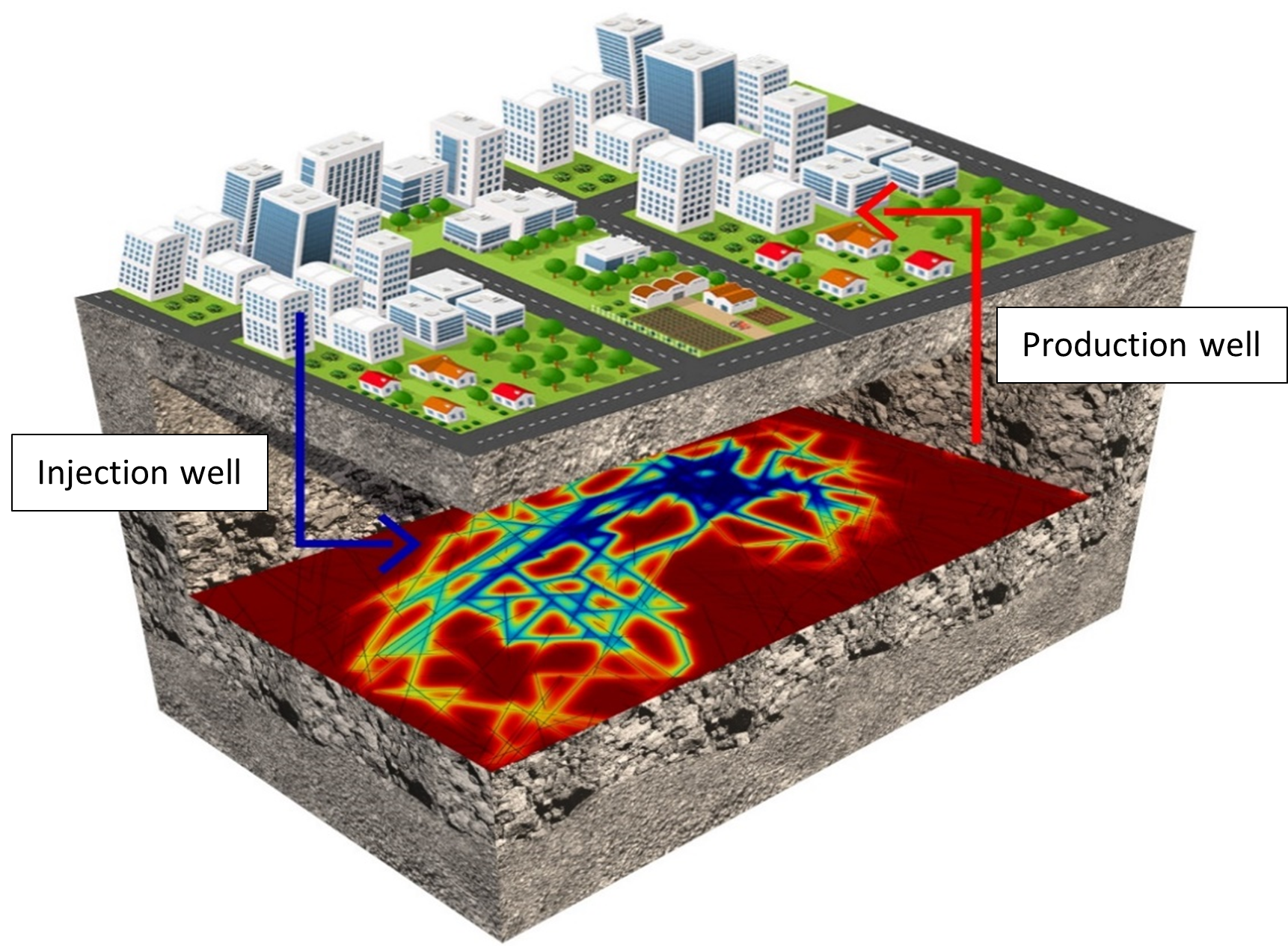

Numerical model from a geothermal site

Researchers at Technische Universität Darmstadt are trying to develop computational models to predict the heat extraction from one of the most investigated MEET demonstration sites: Soultz-sous-Forêts. Possibility of colder fluid injection than the current operational fluid shows potential economic advantages. Geothermal field development may trigger small earthquakes and some of the projects have been terminated due to this reason. With reducing the temperature of the injection fluid, there are high chances of inducing seismicity in the field. However, their results indicate very minimal impact of thermal stress evolution and its extent is limited only in the vicinity of the injection and production wellbores. This may suggest that future studies on seismicity prediction may be constrained in a very small region and their impact will be extremely small. Possibility of CO2 as a working fluid for this geothermal site is also investigated. From the operational point of view, they see no impact of fluid production temperature after 100 years of operation using water and 300 years using CO2 as the working fluid.

One of the major heat losses are associated with the wellbore heat exchange during the injection and production operations. However, this aspect is usually neglected in the computational investigations. Research shows that by considering the wellbore heat exchange, concerns regarding the seismic events reduces. As the injected fluid reaches the bottom of the wellbore at higher temperature than the injected temperature, possibility of thermal shock reduces. Consideration of this effect provides a better estimation of the final production fluid temperature and the total energy extraction. Experience from Soultz-sous-Forêts enables researchers to create a roadmap for future geothermal field developments through appropriate consideration of well placement and reservoir characterization. Developed models under the MEET framework may help associated industries to optimize the production plan. Through this project, the gap between geologists and engineers can be narrowed down by connecting the computational models with field investigations. Computational models empowered the researchers at TU Darmstadt to understand the most effective parameters governing the fluid production temperature, mass flow rate and the energy extraction and geologists may focus on these key parameters for a quick estimation before reaching any conclusion.

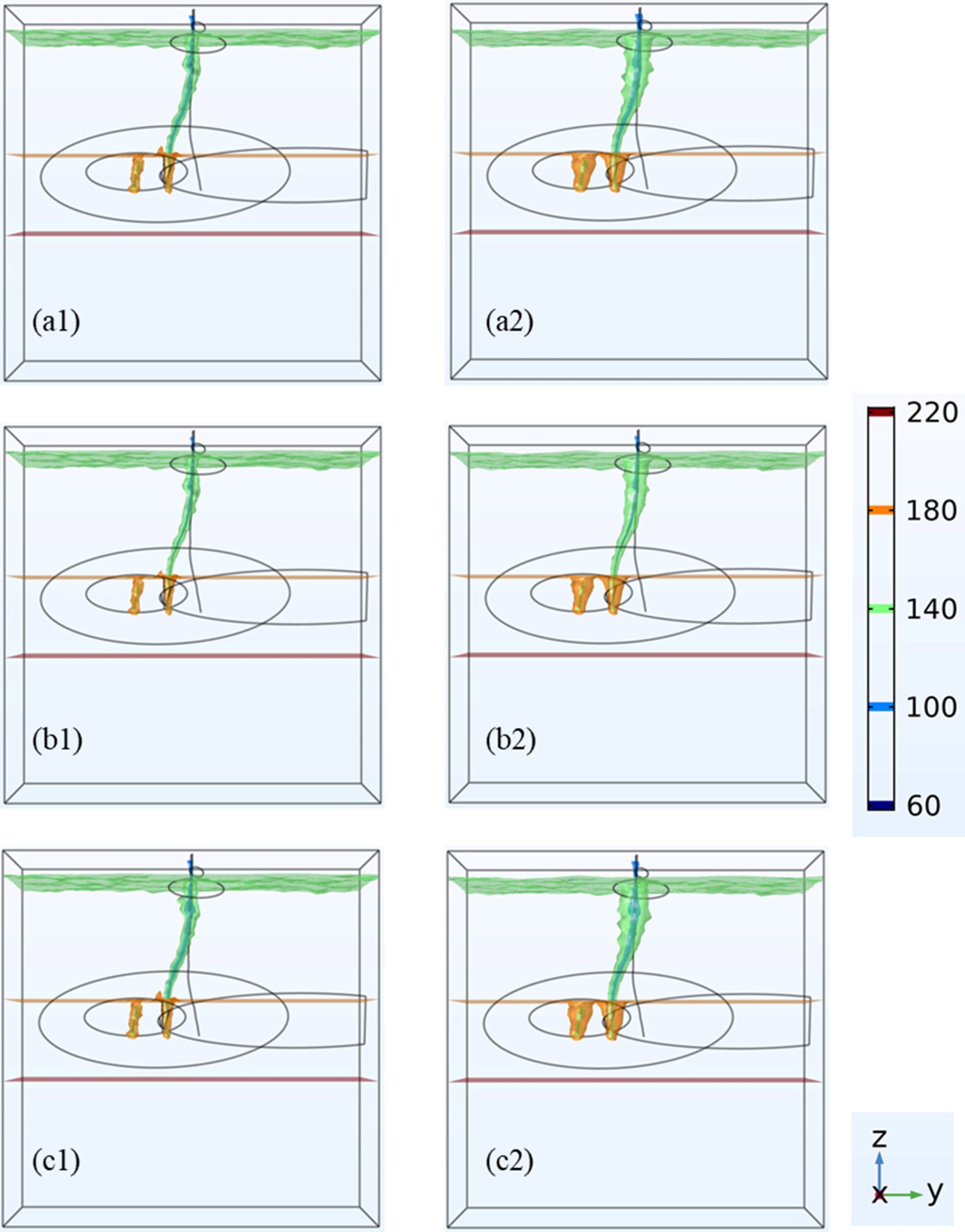

Temperature plume development for (a1) 20 kg/s injection rate at 40 and 50 years, (a2) 20 kg/s injection rate at 40 and 300 years, (b1) 20 kg/s injection rate at 70 and 50 years, (b2) 20 kg/s injection rate at 70 and 300 years, (c1) 50 kg/s injection rate at 40 and 50 years, (c2) 50 kg/s injection rate at 40 and 300 years.