In the frame of the H2020 MEET project, a fibre-optic cable has been deployed on July 30th in the 2.2 km-deep observation well EPS-1 in the Soultz-sous-Forêts geothermal site.

Prior to field operation, ESG was in charge of the risk assessment, technical specifications, tender analysis and well logging company selection.

This descent, the second one conducted during the project, has been coordinated by FEBUS OPTICS and supervised by ESG. The fibre deployment is performed in parallel to the installation of an ORC unit on site, inducing a decrease in the temperature reinjection, from 70°C to 40°C, valorising additional calories on Soultz-sous-Forêts geothermal plant. This colder reinjection could induce variations in the physical properties of the environment that the fibre optic will be able to observe (temperature variations, pressure changes, induced seismicity).

The aim of the fibre optic is indeed to monitor:

- Temperature and strain using Distributed Temperature Sensing (DTS) and Distributed Strain and Temperature Sensing (DSTS).

- Acoustic events using Distributed Acoustic Sensing (DAS).

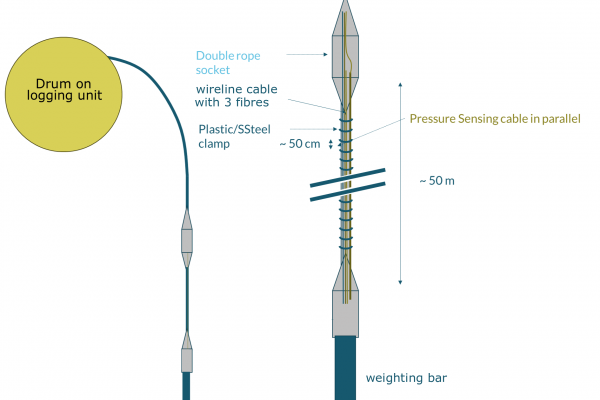

To complete this set of data, a tool has been developed by FEBUS OPTICS, implementing, in parallel to the fibre-optic wireline, a thinner fibre-optic cable more sensitive to pressure variations (Figure 1). This tool deployed along 50 m at the end of the wireline, in the bottom of EPS-1 well will then allow the observation of environmental pressure changes due to the colder reinjection. The FO cable reaches the crystalline basement (granite) in EPS1 open hole.

Figure 1: Tool assembly installed at the bottom of EPS-1 observation well

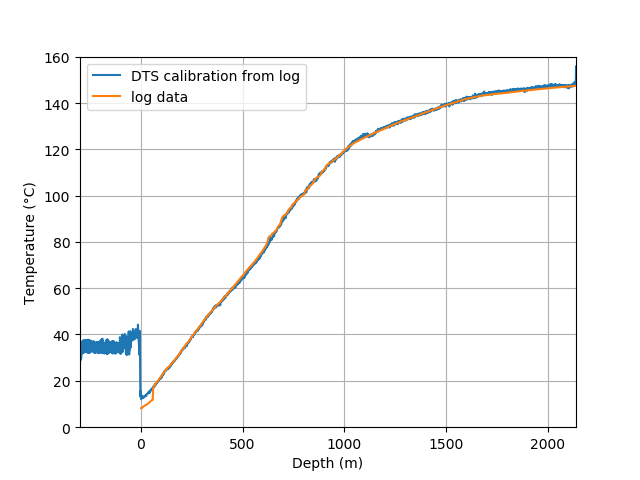

In order to check the correct deployment of the fibre along EPS-1, temperature, strain and acoustic acquisition were run using FEBUS OPTICS’s set of instruments (DTS, DSTS and DAS). First results indicate the success in the descent of 2 189 m of fibre-optic wireline down to the open-hole part of EPS-1 well. Unfortunately, after around 1 000 m of deployment of the wireline, a loss of signal is observed at the beginning of the 50 m-long tools located at the end of the fibre. The investigation is in progress to determine the origin of this break. However, above this point, approximately 2 140 m of Fiber Optic Cable, sensitive to temperature and acoustics has been successfully and durably deployed (see fig 2). It should be possible to investigate quasi-static pressure changes from acoustic sensing at very low frequency. This will be tested during ORC implementation and cold re-injection tests.

Figure 2: Left: Operation setup around the EPS-1 well head, Soultz-sous-Forêts (France) Right: First results of temperature measurements along the fibre using FEBUS’s DTS. We observe that the cable has been successfully deployed until the well bottom and that DTS results are in accordance with previous conducted temperature logging.